In an period defined by environmental consciousness and resource scarcity, the producing sector faces unprecedented stress to adopt sustainable methods. customers, regulators, and stakeholders significantly demand from customers accountability, pushing corporations to attenuate their environmental footprint without having compromising effectiveness or item high quality. conventional solidification procedures for chemical substances, resins, waxes, and meals components generally slide quick, contributing to content waste, substantial Electricity intake, and operational inefficiencies. nevertheless, Sophisticated solidification technologies features a robust Option. Pastillation, a course of action that forms molten goods into uniform, cost-free-flowing pellets, is emerging for a cornerstone of eco-welcoming manufacturing, enabling enterprises to noticeably cut down waste, conserve Power, and boost All round operational sustainability. By partnering which has a reliable pastillator machine supplier, companies can leverage this technology to achieve these Positive aspects and shift towards a greener, much more rewarding long term.

Table of contents:

Mastering product performance: a lot less enter, a lot more Output

Powering Down manufacturing: Electricity effectiveness in Solidification

created to very last: Durability, Reliability, and lowered Lifecycle squander

Precision development: reducing squander from manufacturing to End-Use

Seamless Integration for a Greener Future

Mastering content performance: much less Input, much more Output

one of many most significant environmental impacts of producing stems from inefficient content utilization. squandered Uncooked resources not simply represent a immediate monetary decline but will also embody squandered Power and means expended during their extraction, processing, and transportation. regular solidification procedures, like flaking or slabbing, can generally result in non-uniform products, fines (dust), or outsized pieces that require additional processing, screening, or are merely discarded as off-specification materials. This inherent inefficiency contributes straight to the squander stream.

Pastillator equipment tackle this problem head-on by means of exact system Handle. The core basic principle requires depositing exactly metered droplets of molten merchandise on to a consistently moving metal belt. since the belt travels, extremely economical cooling techniques (generally working with water sprayed about the underside in the belt) promptly and uniformly solidify the droplets into distinct, persistently sized pastilles. This managed cooling stops the formation of irregular designs or a wide particle sizing distribution.

The end result can be a significant generate of on-spec merchandise. since the pastilles are uniform in size, form, and bodyweight, downstream procedures like packaging, dosing, melting, and mixing come to be appreciably a lot more exact and successful. There exists a lot less need for screening out undesired fractions, and the quantity of merchandise missing as a consequence of bad managing features or rejection is substantially lessened. By maximizing the conversion of molten Uncooked materials into usable final item, pastillation inherently minimizes source depletion and waste technology at the resource, forming the initial pillar of its eco-helpful credentials. This efficiency translates immediately into decrease raw materials charges in addition to a lowered environmental burden linked to content sourcing and disposal.

Powering Down output: Energy effectiveness in Solidification

Power intake is another critical Think about the environmental footprint of manufacturing functions. large Power use not merely will increase operational costs but will also contributes substantially to greenhouse gas emissions, significantly If your Strength source is fossil fuel-based mostly. Solidification processes could be Strength-intense, especially Individuals necessitating prolonged cooling periods, comprehensive submit-processing like grinding, or inefficient warmth transfer mechanisms.

Modern pastillators are engineered with energy efficiency for a Most important layout consideration. the usage of very conductive steel belts coupled with optimized cooling programs (usually utilizing immediate Call cooling ideas with exactly controlled h2o move) facilitates fast and successful heat transfer from the molten product or service. This accelerates the solidification approach, cutting down the overall time the product demands to invest under cooling disorders. in comparison with cooling huge blocks or depending on air cooling, this method calls for drastically a lot less Power per device of merchandise processed.

On top of that, the immediate development of regularly sized pastilles generally eradicates the necessity for energy-intense downstream sizing reduction methods, including crushing or grinding, that are typical with slab or block solidification. Grinding processes are notorious not simply for his or her large Vitality intake but will also for producing heat and mud, which may require supplemental Power for dust selection and mitigation methods. By producing the specified final form issue right, pastillators streamline the manufacturing line and eliminate these energy-hungry measures. This reduction in energy intake specifically lowers a facility’s carbon footprint and operational expenses, aligning perfectly with eco-friendly producing objectives and improving the bottom line.

developed to very last: longevity, trustworthiness, and lowered Lifecycle squander

The sustainability of a production system isn't almost the resources and Electrical power applied through creation; What's more, it will involve the lifecycle from the machines alone. Machinery that regularly breaks down, requires constant alternative areas, or has a short operational lifespan contributes appreciably to waste – equally regarding discarded components plus the sources consumed in producing replacements.

substantial-good quality pastillator techniques are typically made from resilient components, with stainless-steel belts staying a standard characteristic known for their longevity, resistance to corrosion, and thermal steadiness. The mechanical components, including the feeding machine (just like a Rotoformer or drop depositor), belt tracking techniques, and discharge elements, are made for continuous operation in demanding industrial environments. This emphasis on robust engineering translates into extensive-term dependability and minimized downtime.

decrease maintenance demands are another critical benefit. nicely-intended pastillators limit dress in and tear on crucial parts. By way of example, The graceful Procedure of the steel belt as well as the non-abrasive mother nature from the pastille formation procedure suggest fewer frequent require for belt replacement compared to other conveying or processing programs. less breakdowns and fewer frequent maintenance translate straight into lowered use of spare elements, lubricants, and servicing fluids above the machine’s life span. deciding on a reputable pastillator device provider who emphasizes top quality construction and presents dependable help even more improves this extensive-term sustainability factor. This deal with toughness minimizes the squander connected with products failure and substitution, contributing to a far more sustainable operational design as a result of longevity and decreased resource usage for repairs.

Precision Formation: reducing Waste from creation to finish-Use

Waste reduction via pastillation extends past the manufacturing plant itself. The Bodily qualities of the ultimate pastille products Perform a vital function in reducing squander through the entire provide chain and during conclusion-use application. The specific Handle inherent in the pastillation method yields pastilles that are typically spherical or hemispherical, uniform in size, and importantly, very low-dusting or nearly dust-free.

This contrasts sharply with products like flakes or powders, which might crank out considerable quantities of dust in the course of managing, transport, conveying, and dosing. Dust signifies dropped solution, potential wellness dangers granulator manufacturers for personnel demanding mitigation measures, and can cause cross-contamination difficulties in delicate apps like food or pharmaceuticals. The cost-free-flowing, non-dusty mother nature of pastilles simplifies product dealing with units, lowers spillage, and makes certain that more in the products reaches its meant last software. For industries evaluating granulation versus pastillation, the lower-dust attribute of pastilles is frequently a determining issue, particularly when considering possibilities from a variety of granulator brands where by dust probable could possibly be larger dependant upon the particular engineering and products.

Furthermore, the uniformity of pastilles aids in exact dosing and rapid, predictable dissolving or melting in downstream procedures. This performance at the point of use – whether it’s Mixing chemicals, incorporating ingredients in foods production, or formulating prescription drugs – usually means considerably less content is wasted on account of inaccurate measurement or incomplete processing. This finish-to-finish effectiveness, from initial solidification to remaining consumption, underscores the holistic waste reduction Rewards supplied by pastillation know-how.

Seamless Integration for the Greener potential

Adopting new, sustainable systems can frequently seem to be complicated, notably when it will involve the perception of an entire overhaul of present production traces. the associated fee, time, and likely disruptions affiliated with this sort of transitions can generate considerable resistance inside of organizations. on the other hand, modern pastillation systems are intended with versatility and integration in mind, supplying a functional Resolution for firms on the lookout to improve their operations. These methods can generally be seamlessly included into current production setups, replacing outdated and less productive solidification stages without having necessitating a root-and-department redesign of your complete process stream. This adaptability not simply lowers the complexity on the enhance course of action but also lowers the barrier to entry for firms striving to boost their sustainability credentials while maintaining enterprise continuity.

On top of that, pastillation technological innovation aligns extremely well with the concepts of the round overall economy. as opposed to classic approaches, fashionable pastillators permit suppliers to attenuate squander by supplying the capability to remelt and reuse off-specification merchandise. The remelted materials can normally be reintroduced in to the feed stream with minimal degradation, resulting in a closed-loop procedure that noticeably lessens squander. This inherent attribute of pastillation encourages source efficiency and content reuse, which happen to be significant tenets of sustainable production and also the circular economic system. By minimizing reliance on virgin elements and avoiding unwanted disposal, corporations can reach significant reductions inside their environmental footprint.

the advantages of pastillation increase further than squander administration. The know-how also supports manufacturing products that prioritize Electricity efficiency and item high quality. With specific control around solidification disorders, pastillation units increase merchandise regularity, lower Vitality use throughout output, and increase Over-all operational performance. These functions enable it to be simpler for businesses to align their procedures with greener, far more liable production tactics. Additionally, The graceful integration of this technological know-how into current setups permits producers to changeover at their own personal tempo, keeping away from high-priced and disruptive shutdowns.

By empowering manufacturers to undertake sustainable tactics with no compromising efficiency or merchandise high quality, pastillators work as enabling systems for the trendy era. they provide companies a chance to obtain tangible progress on their sustainability journey even though retaining the aggressive edge necessary in right now’s industry. The combination of fabric discounts, Strength reductions, Increased item high quality, and minimized waste makes pastillation a strong Instrument for corporations trying to get to accelerate their change in direction of a lot more accountable and long run-All set production techniques. Along with the escalating desire for greener generation procedures, embracing these kinds of adaptable and efficient technologies could demonstrate to generally be a critical stage for enterprises planning to prosper within an progressively sustainability-conscious entire world.

The imperative for sustainable producing is undeniable. Pastillation technological know-how provides a persuasive and sensible solution for businesses trying to find to lower their environmental impression although boosting operational effectiveness and solution excellent. By making sure exact substance utilization, reducing Power use as a result of optimized cooling, supplying prolonged-expression trustworthiness that cuts down products lifecycle squander, and manufacturing uniform, very low-dust end items that lessen losses throughout the price chain, pastillators characterize a substantial phase ahead in eco-friendly production. For corporations planning to embrace greener production techniques and get a aggressive edge, Discovering advanced pastillation devices is very important. providers like CONSOL present point out-of-the-art pastillator devices made to supply these sustainability benefits, aiding industries proficiently solidify their products as well as their determination to a far more sustainable upcoming.

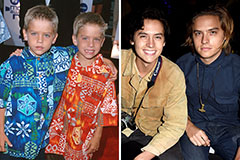

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Destiny’s Child Then & Now!

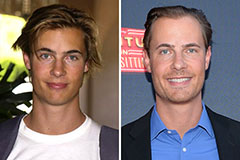

Destiny’s Child Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!